Diki Diameter Graphite Electrodes Tsvimbo YeMagetsi Arc Furnace MuSimbi Uye Foundry Indasitiri

Technical Parameter

Chati 1:Technical Parameter For Diki Diameter Graphite Electrode

| Diameter | Chikamu | Resistance | Flexural Strength | Young Modulus | Density | CTE | Ash | |

| Inch | mm | μΩ·m | MPa | GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chati 2: Ikozvino Kutakura Kugona KweDiki Dimita Graphite Electrode

| Diameter | Current Load | Current Density | Diameter | Current Load | Current Density | ||

| Inch | mm | A | A/m2 | Inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Zvakanakira

1.Anti-oxidation kurapwa kwehupenyu hurefu.

2.High-kuchena, yakakwirira-density, yakasimba kugadzikana kwemakemikari.

3.High machining accuracy, good surface finishing.

4.High mechanical simba, yakaderera magetsi kuramba.

5.Kurwisana nekuputika & spalling.

6.Kupikisa kwepamusoro kune oxidation uye kupisa kwekushisa.

Main Application

- Calcium carbide inonyungudutsa

- Carborundum kugadzirwa

- Corundum kunatsa

- Masimbi asingawanzo kunyunguduka

- Ferrosilicon chirimwa refractory

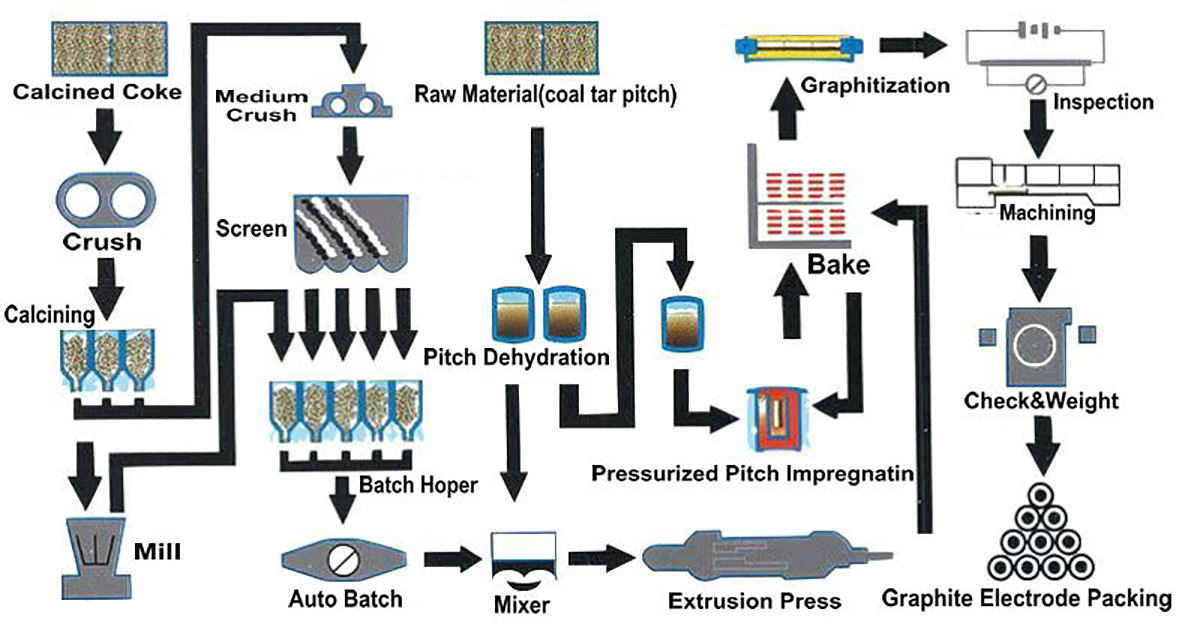

RP Graphite Electrode Production Process

Surface Quality Ruler

1.Kukanganisa kana maburi haafanire kudarika zvikamu zviviri pa graphite electrode surface, uye zvikanganiso kana hukuru hwemakomba hazvibvumirwi kudarika data iri patafura iri pasi apa yakataurwa.

2.Hapana kutsemuka kwakachinjika pamusoro pe electrode surface.Pakutsemuka kwenguva refu,kureba kwayo hakufaniri kudarika 5% ye graphite electrode circumference,hupamhi hwayo hunofanira kuva mukati me 0.3-1.0mm range.Longitudinal crack data pazasi 0.3mm data inofanira kuva vasina basa

3. Kufara kwenzvimbo ine rough (dema) panzvimbo yegraphite electrode haifanire kunge isingasviki 1/10 yegraphite electrode circumference, uye kureba kwenzvimbo yakakasharara (dema) inopfuura 1/3 ye graphite electrode kureba. hazvibvumidzwe.