Iyo Yekugadzira Maitiro eiyo Graphite Electrode

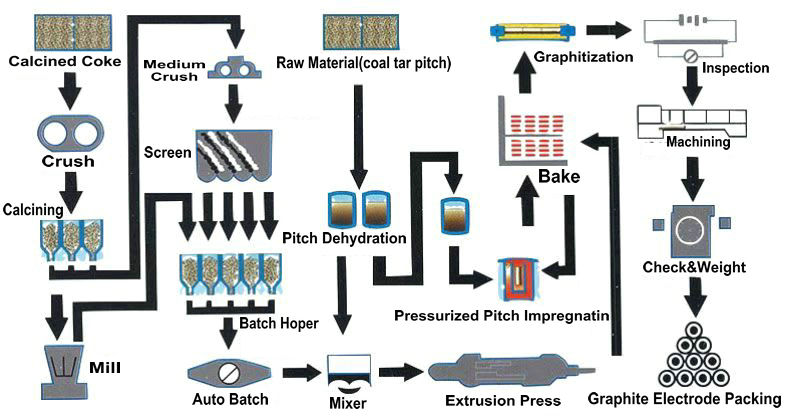

Graphite electrode imhando yepamusoro tembiricha inodzivirira graphite conductive zvinhu inogadzirwa nekushandisa petroleum coke, tsono coke seyakaunganidzwa, marasha asphalt sebinder, mushure mekutevedzana kwemaitiro akadai sekusanganisa, kuumba, kugocha, kunyura, graphitization uye mechanic process.

Iwo makuru ekugadzira maitiro eiyo graphite electrode ndeaya anotevera:

(1) Calcination.Petroleum coke kana asphalt coke inoda kugadzirwa, uye tembiricha yecalcination inofanira kusvika 1300 ℃, saka kurongeka kubvisa zvizere zvinhu zvinoputika zviri mucarbon raw materials, uye kuvandudza density yechokwadi, simba remuchina uye magetsi ecoke.

(2) kupwanya, kuongorora, uye zvigadzirwa.Iyo calcined kabhoni mbishi zvinhu inoputswa uye yakaongororwa muzvikamu zvimedu zvehukuru hwakatarwa, chikamu checoke chinogayiwa kuita hupfu hwakatsetseka, uye musanganiswa wakaoma unoiswa zvinoenderana nefomati.

(3) Mix.Munzvimbo yekudziya, iyo yakawanda yakaoma musanganiswa wezvikamu zvakasiyana-siyana inosanganiswa neiyo yakawanda binder, yakavhenganiswa uye yakakanya kuti igadzirise paste yepurasitiki.

(4) kuumba, pasi pechiito chekunze kwekumanikidza (extrusion forming) kana pasi pechiito chepamusoro frequency vibration (vibration forming) kudzvanya paste mune imwe chimiro uye yakakwirira density yeraw electrode (billet).

(5) Kubika.Iyo electrode yakasvibirira inoiswa muchoto chakakosha chekugocha, uye iyo metallurgical coke poda inozadzwa uye yakavharwa ne electrode mbishi.Pakupisa kwepamusoro kwemumiririri wekubatanidza we1250 ℃, iyo yekugocha kabhoni electrode inogadzirwa.

(6) Akachena.Kuti uvandudze kusimba uye kusimba kwemagetsi ezvigadzirwa zve electrode, electrode yekugocha inotakurwa mumidziyo yemagetsi yakakwira, uye iyo yemvura dipping agent asphalt inotsikirirwa mugomba remhepo re electrode.Mushure mekunyudzwa, kugocha kunofanira kuitwa kamwe chete.Zvinoenderana nekuita zvinodiwa zvechigadzirwa, dzimwe nguva iyo impregnation uye yechipiri kugocha kunofanirwa kudzokororwa 23 nguva.

(7) graphitization.Iyo yakabikwa kabhoni electrode inotakurwa muchoto chegraphitization, yakafukidzwa nezvinhu zvekudzivirira.Nekushandisa nzira yekudziya yemagetsi yakananga kugadzira tembiricha yepamusoro, iyo kabhoni electrode inoshandurwa kuita graphite electrode ine graphite crystal chimiro patembiricha yepamusoro ye2200 ~ 3000 ℃.

(8) kugadzira.Zvinoenderana nezvinodiwa zvekushandisa, iyo graphite electrode blank surface inotendeuka, flat end surface uye screw maburi ekubatanidza kugadzirisa, uye joint yekubatanidza.

(9) Iyo graphite electrode ichaiswa zvakanaka mushure mekupfuura kuongororwa uye kutumirwa kumushandisi.

Nguva yekutumira: Jun-01-2023