Diki Dhiyamita Furnace Graphite Electrode yemagetsi arc choto chesimbi uye foundry indasitiri.

Technical Parameter

Chati 1:Technical Parameter For Diki Diameter Graphite Electrode

| Diameter | Chikamu | Resistance | Flexural Strength | Young Modulus | Density | CTE | Ash | |

| Inch | mm | μΩ·m | MPa | GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chati 2: Ikozvino Kutakura Kugona KweDiki Dimita Graphite Electrode

| Diameter | Current Load | Current Density | Diameter | Current Load | Current Density | ||

| Inch | mm | A | A/m2 | Inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Chati 3: Graphite Electrode Saizi & Kushivirira Kune Diki Diameter Graphite Electrode

| Nominal Diameter | Chaiyo Diameter(mm) | Nominal Length | Kushivirira | |||

| Inch | mm | Max. | Min. | mm | Inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Main Application

- Calcium carbide inonyungudutsa

- Carborundum kugadzirwa

- Corundum kunatsa

- Masimbi asingawanzo kunyunguduka

- Ferrosilicon chirimwa refractory

Mirayiridzo Kupa uye Kushandisa Kune Graphite Electrodes

1.Bvisa chivharo chekudzivirira chegomba idzva re electrode, tarisa kana thread iri mugomba re electrode yakakwana uye thread haina kukwana, taura nevanyanzvi veinjiniya kuti vaone kana electrode inogona kushandiswa;

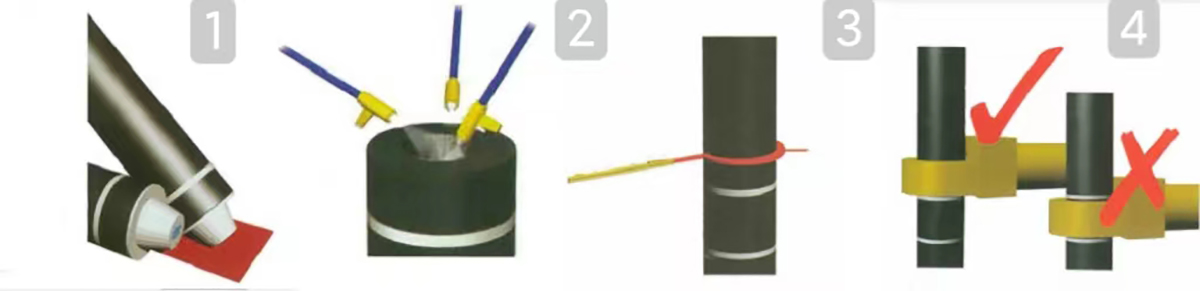

2.Kurukura hanger ye electrode mugomba re electrode kune imwe mugumo, woisa mutsara wakapfava pasi peimwe mugumo we electrode kuti usakuvadza chibatanidzwa che electrode;(ona pic1)

3.Shandisa mweya wakatsikirirwa kuridza huruva uye sundries pamusoro uye gomba rekubatanidza electrode, uye wobva wachenesa pamusoro uye chibatanidza che electrode itsva, chichenese nebhurasho;(ona pic2)

4.Simudza electrode itsva pamusoro pe electrode yakamirira kuti ienderane negomba re electrode uye uwire zvishoma nezvishoma;

5.Shandisa yakakosha torque kukosha kukiya zvakanaka electrode;(ona pic3)

6.Clamp inobata inofanira kuiswa kunze kwetambo yearamu.(ona pic4)

7.Munguva yekunatsa, zviri nyore kuita electrode kuonda uye kukonzera kuputsa, kubatana kudonha, kuwedzera kushandiswa kwe electrode, ndapota usashandise electrode kusimudza carbon content.

8.Nekuda kwezvinhu zvakasiyana-siyana zvinoshandiswa nemugadziri wega wega uye maitiro ekugadzira, maitiro emuviri uye emakemikari emagetsi emagetsi uye majoini emugadziri wega wega. Saka mukushandiswa, pasi pemamiriro ezvinhu, Ndokumbira usasanganise maelectrodes uye majoini anogadzirwa nevagadziri vakasiyana.