Yakakwira Density Diki Diki Diki Birafita Electrode YeLadle Furnace Blast Furnace Mukunyunguduka Simbi

Technical Parameter

Chati 1:Technical Parameter For Diki Diameter Graphite Electrode

| Diameter | Chikamu | Resistance | Flexural Strength | Young Modulus | Density | CTE | Ash | |

| Inch | mm | μΩ·m | MPa | GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chati 2: Ikozvino Kutakura Kugona KweDiki Dimita Graphite Electrode

| Diameter | Current Load | Current Density | Diameter | Current Load | Current Density | ||

| Inch | mm | A | A/m2 | Inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Chati 3: Graphite Electrode Saizi & Kushivirira Kune Diki Diameter Graphite Electrode

| Nominal Diameter | Chaiyo Diameter(mm) | Nominal Length | Kushivirira | |||

| Inch | mm | Max. | Min. | mm | Inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Main Application

- Calcium carbide inonyungudutsa

- Carborundum kugadzirwa

- Corundum kunatsa

- Masimbi asingawanzo kunyunguduka

- Ferrosilicon chirimwa refractory

Mirayiridzo Kupa uye Kushandisa Kune Graphite Electrodes

1.Shandisa maturusi anokosha ekusimudza kuti ararame graphite electrode kudzivisa kukuvadzwa panguva yekufambisa.(ona pic1)

2.Graphite electrode inofanira kuchengetedzwa kubva pakunyoroveswa kana kunyorova nemvura, sinou, ichengetedzwe yakaoma.(ona pic2)

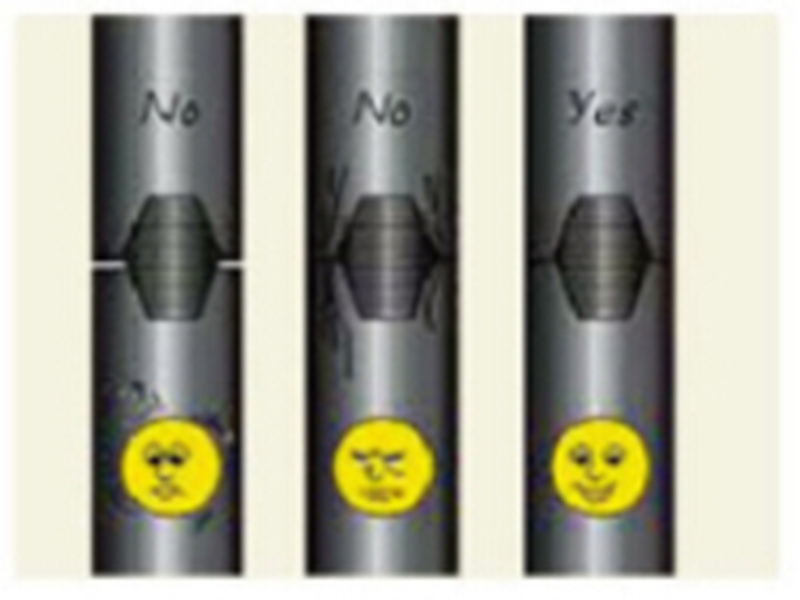

3.Kunyatsotarisa usati washandisa iva nechokwadi chokuti socket uye nipple thread yakakodzera kushandiswa, kusanganisira kuongororwa kwepitch, plug. (ona pic3)

4.Chenesa tambo dze zamu nezvigadziko nemhepo yakamanikidzwa.(ona pic4)

5.Usati washandisa, iyo graphite electrode inofanira kuomeswa muchoto, kupisa kwekuoma kunofanira kuva pasi pe150 ℃, nguva yakaomeswa inofanira kunge inopfuura 30hours. (ona pic5)

6.Graphite electrode inofanira kubatanidzwa zvakasimba uye zvakananga neakakodzera kuomesa torque.(ona pic6)

7.Kudzivirira kuparara kwe graphite electrode, isa chikamu chikuru munzvimbo yakaderera uye chikamu chiduku panzvimbo yepamusoro.