Graphite Electrode Inoshandiswa Kune Corundum Kunatsa Magetsi Arc Furnace Diki Diameter Furnace Electrodes

Technical Parameter

Chati 1:Technical Parameter For Diki Diameter Graphite Electrode

| Diameter | Chikamu | Resistance | Flexural Strength | Young Modulus | Density | CTE | Ash | |

| Inch | mm | μΩ·m | MPa | GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chati 2: Ikozvino Kutakura Kugona KweDiki Dimita Graphite Electrode

| Diameter | Current Load | Current Density | Diameter | Current Load | Current Density | ||

| Inch | mm | A | A/m2 | Inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Chati 3: Graphite Electrode Saizi & Kushivirira Kune Diki Diameter Graphite Electrode

| Nominal Diameter | Chaiyo Diameter(mm) | Nominal Length | Kushivirira | |||

| Inch | mm | Max. | Min. | mm | Inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Main Application

- Calcium carbide inonyungudutsa

- Carborundum kugadzirwa

- Corundum kunatsa

- Masimbi asingawanzo kunyunguduka

- Ferrosilicon chirimwa refractory

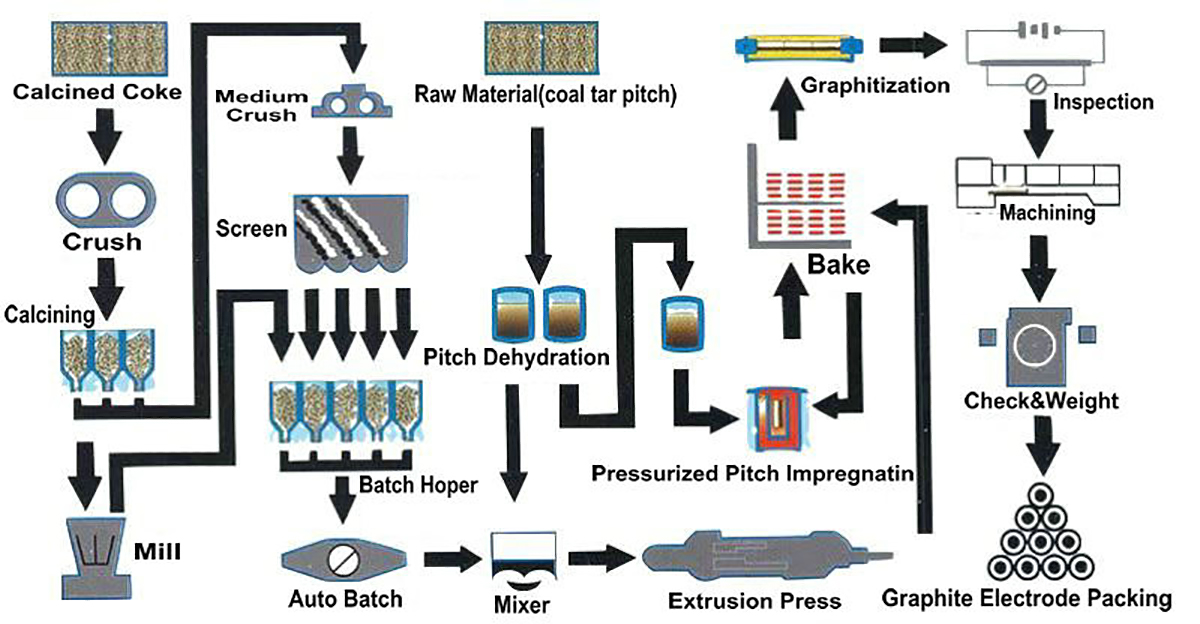

RP Graphite Electrode Production Process

Gufan Advantages

1. Yakagadzirwa kubva kumhando yepamusoro ye graphite zvinhu, madiki edu madiki magirafu emagetsi anovakwa kuti amire kutonhora kwakanyanya uye anopa yakanakisa magetsi emagetsi. Izvi zvinoita kuti kunyungudika kwakagadzikana uye kunoshanda, zvichiita kuti pave nemhando yepamusoro yechigadzirwa uye kuderedza kushandiswa kwesimba.

2. Ukuru huduku hwema electrode aya hunobvumira kutonga kwakanyatsojeka pamusoro pekugadzirisa kunyunguduka, zvichiita kuti zvive zvakakwana kune zvikumbiro zvinoda kururamisa kwepamusoro uye migumisiro yakanaka. Kunyangwe iwe uri kugadzira alloys kana kunatsa simbi, maelectrode edu achakubatsira iwe kuzadzisa mhedzisiro yaunoda nekurongeka kusingaenzaniswi.

3. Madhigirii edu maduku magirafu emagetsi akakodzera kune zvakasiyana-siyana zvemabhizimisi, kusanganisira kugadzira simbi, kushandiswa kwemakemikari, uye kukanda simbi. Hazvina mhosva nehukuru hwekushanda kwako, maelectrode edu anogona kugadzirwa kuti asangane nezvinodiwa zvako.

4. Mukugadzira simbi, madhiyamita edu ma graphite electrode anoshandiswa mumagetsi arc furnaces, kwaanoita basa rakakosha mukugadzirwa kwesimbi yepamusoro. Saizi yavo diki inobvumira kunyatso kudzora pamusoro pekunyunguduka, kuve nechokwadi chemhedzisiro inowirirana uye kuderedza tsvina.

5. Mukugadzirwa kwemakemikari, ma electrode edu anokosha pakugadzirwa kwe calcium carbide uye kunatswa kwecarborundum. Aya maitiro anoda chaiyo tembiricha yekudzora, iyo maelectrode edu anouyisa nekunyatso.

6. Pakukanda simbi, madhigirii edu madiki magirafu emagetsi anoshandiswa mukunyunguduka kwesimbi isingawanzo uye Ferrosilicon zvirimwa. Iyo yepamusoro conductivity ye graphite inobvumira kunyunguduka kwakanaka kwesimbi, zvichikonzera kukurumidza kutenderera kwekugadzira uye kukwirira kwese kubereka.